Another test about the casting grinding balls is to see the distribution of Martensite, Austenite, and Carbon water mixture. This process can look at the changes in the balls’ inner structure due to the heat treatment.

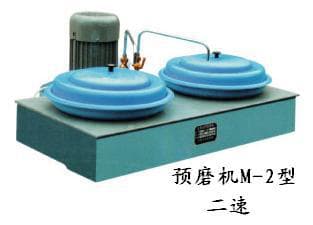

Metallographic pre-mill machine

M-2 type Double Desktop Dual Speed Metallographic pre-mill machine, is a wet grinder. It adopts variety of different size water-resistant sandpaper, to polish the all kinds of samples of metals and alloys. Using this pre-mill machine, On the one hand, mechanical polishing instead of manual operation so that to improve the efficiency of sample preparation. On the other hand, it can be completely removed heating traces on the surface which is produced during sample cutting, polished organization for further microscopic determination. It can help cut the balls to do the further test.

Inverted Metallurgical Microscope

Trinocular tube: Three head upside down, hinged observation tube, 45 ° tilt, magnification: 100 times -1250 times, the nosepiece: four-hole converter; Mechanical tube length: 160mm; eyepiece: flat-field eyepiece 10X / Φ18; objective: achromatic objective lens PL10X, PL40X, PL100X / oil; pupil distance: 55mm-75mm;

stage: square table 175mm × 145mm, moving range: 30 × 30mm; reflective lighting: 6V / 20W halogen lamp; brightness adjustable focusing mechanism: 10mm coaxial coarse focusing mechanism with a locking device, to fine-tune the grid value: 0.002mm, a lighting device: polarizing device.